my sharpening skills suck, so 154 at least allows me to cut through butter without warming the blade

my sharpening skills suck, so 154 at least allows me to cut through butter without warming the blade

Larrin has indeed made quite the pitch but it's subtle as to many it just appears to be raw data. What he has in fact done is create a model of performance which can be very misleading as the tests he uses have to be interpreted correctly. There has also been zero attempt to actually use real world testing to validate his testing methods. As it stands currently, his 'science' would not even be accept at the high school level because the model has not even been attempted to prove correlation to reality. I have challenged this view publicly and you wouldn't believe the amount of people that grab the torches and pitchforks to defend Larrin.

He maintains that he has not created a model and the tests are just the tests. The problem is that he draws conclusions based on these tests of what makes a 'better' steel and at that point he's using it as a model.

Despite this, anybody and seemingly everybody, has taken his test and held them out to be the de facto proof that some steels are superior to others. Magnacut being one of those steels that he praises highly as an all-around balanced steel. The fact is, depending on how you use a knife and the geometry you are using on the knife, you could end up with a very poorly suited steel if you go by his charts and data. I personally choose steels counter to everything he praises in general and steels such as AEB-L or other simple steels tend to be ideal in my use. I prefer acute edge geometry and these higher carbide volume steels do poorly at these geometries.

You are absolutely correct about the commonly praised steels (powder metal, higher carbide) NOT actually being tough at all, this is the case at a very small cross section like the apex of a knife. They do APPEAR quite tough when looked at and tested only in heavier cross sections. In short, if you like edges over 15 DPS and do not see impacts AND do not sharpen until the knife is so dull that it barely passes as a cutting tool then you may find those types of steels preferable. Myself personally, their attributes tend to work against everything I value in a cutting tool. Ease of grinding, resistance to damage in thin cross sections, etc.

If you don't like MagnaCut, there's always 3V, AEBL, Cru-Wear, M4, K390. Or even CPM-154 which I know for a fact has performed well in the field for many avid outdoorsmen and hunters.

On the other hand, I also like 52100 quite a bit.

If you know how you will use a knife, it's not all that difficult to find a steel that will satisfy...assuming it has been heat treated properly. But you need to know what you want and what the trade-offs are.

There's a lot of factors that have to be taken on faith unless you're building them yourself.

Probably shouldn't turn this thread about Spyderco Fanboys into a lynch mob against Larrin. Fact is, Sal Glesser of Spyderco, as well as several other top manufacturing concerns turn to him for information and put it to use. The reports, good and bad about the knives are widely available.

There's nothing civil about this war.

It's certainly not my intention to flame Larrin but the point is that he wields a very large influence on the knife world and I believe has led many astray intentionally or not. Spyderco is a great company but they certainly don't have everything figured out and they are chasing the dragon on steels, IMO. Simple steels have worked well for 100's of years and chasing the perfect steel seems to be what most knife 'people' have become.

I don't doubt Magna-cut makes a decent or better knife but the matter is more to do with how it's promoted as though it's up there with the second coming of Christ. The fact is, geometry and cross section make far more of a different than almost any other factor of knife performance. Larrin agrees with this reality when it comes to performance, yet tirelessly argues steel characterstics so everyone is hung up on that fact alone it seems.

I appreciate a materials science approach to knife steel and blade design, partially because I've worked in that field but mostly because I strongly prefer blades that maximize toughness and edge retention. I'm willing to put up with a little corrosion and work harder to sharpen. What I really hate is chipping a blade, or ruining the tip by dropping the knife.

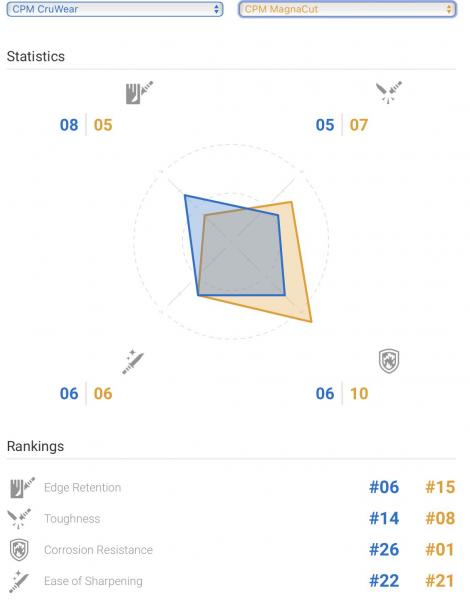

I was about to try a Cruwear blade, but Magnacut looks superior in every way.

“There is no growth in the comfort zone.”--Jocko Willink

"You can never have too many knives." --Joe Ambercrombie

Not directed at you @RealSelf, but your quote is relevant.

I've got no dog in this fight, but I'd like to point out that "chasing the dragon" is what people do. Let's just look into our own little sphere when it comes to pistols, optics, emitters, calibers, lumens, etc. As a manufacturer, it would be foolish to NOT offer what people are looking for, and it's equally foolish to not chase the dragon on the customers' behalf, as well. It does turn into a vicious cycle, but as long as we see it for what it is, it's all good. A fool and his money, and all that....

I think there's another point that most people tend to forget, and it's that unless you commission a knife from a knifemaker, you're not getting a piece made for you. You're getting a piece for the collective community. There is rarely a knife that's "perfect" for even a few people, much less the whole group. So pick what works for you and leave the others to "chase the dragon" or buy performance (seems like a recurring theme on PF)

I think you'll find that the Cru-Wear is a bit tougher, edge holding is mostly a push, and of course the MagnaCut being superior in regard to stain resistance. Cru-Wear takes a screaming edge, and Magna-Cut is close in that regard. Neither tough to sharpen imho.

Some makers have had issues with the "finish" on MagnaCut. Nate Carothers of Carothers Performance Knives and Josh from REK Knives come to mind there.

I love both steels. Cru-Wear took over for me from D2, which I have quite a few blades made from.

Years ago, Master Smith P.J. Tomes told me that the closest stainless to his forged and cryo'd 52100 was 12c27. I haven't spoken to him in a while...not sure where AEBL would fall on his list.

It's a fascinating field. I took classes at NYU in Materials Science when I was in junior high...and enjoyed it very much. Now I just love watching the continuum of "advances" with tweaks to various steels, both their chemistry and heat treat.

There's nothing civil about this war.

The comparison from BladeHQ's steel page shows Magnacut slightly tougher than Cruwear:

“There is no growth in the comfort zone.”--Jocko Willink

"You can never have too many knives." --Joe Ambercrombie

FWIW, Blade HQ's charts over the years have been called into question...though personally I've found them useful in the past as rough synopses of a steel's characteristics.

YMMV, of course. Just reporting what I've encountered in that regard.

There's nothing civil about this war.

What do you mean 'issues with the finish'? As in, it is very low grindability so time-consuming and expensive to finish? If so, that is one of the things Larrin has said was supposed to separate Magnacut from other Vanadium carbide steels. I've always been skeptical of this so it wouldn't surprise me.