I'm liking this MC more and more.

As noted in my previous update, there was polishing residue in many places on the outside, and a (new) slight grittiness to the trigger press when it came back from Ruger. I did a detail strip to solvent-clean everything. Found several deposits of what appeared to be red garnet polishing/grinding compound in various places around the insides. I deburred rough edges and knocked down assorted nastiness throughout. Kept all the springs original. For a piece of hardware that is still within the parameters of original design intent, the result is quite pleasing.

I also

swapped out the grip to a Hogue NFG rubber unit, with a couple minor adjustments, and that's working well.

The rear sight pin started to walk out, so I have Loctited it. If that isn't enough, there are several more advanced strategies to try.

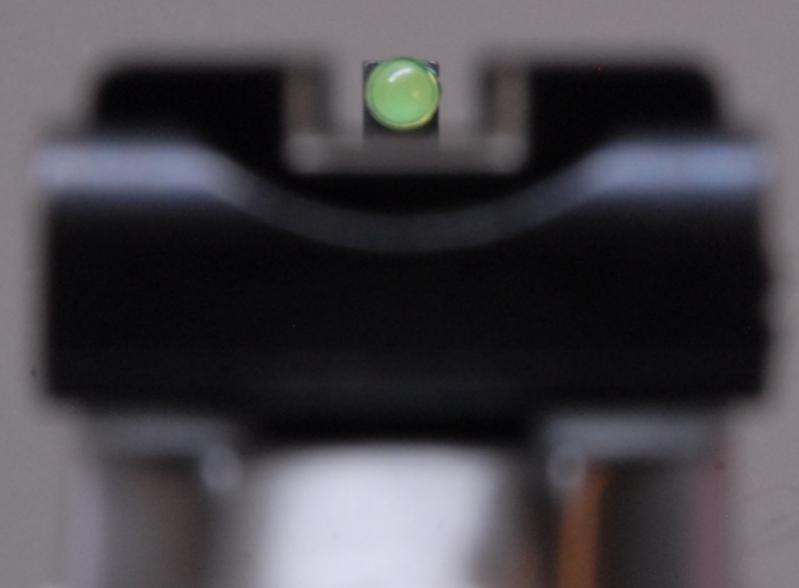

The front sight has bugged me, which brings me back to this thread. Original equipment is this

Novak fiber-optic. Unlike most FO sights, which are cut more or less square, the ends on this element are rounded buttons or “lenses.” The light intensity is not consistent, with areas that are brighter and darker distributed unevenly around the thin edges of the button. It doesn’t seem to be precisely dimensioned like a machined or otherwise tooled part, which is almost to be expected given the

installation method for the FO element described on the Novak web site. That process is inherently uncontrolled and I believe can be expected to deliver random results. Frankly, the sample photographed by Novak for the first link in this paragraph looks worse than mine.

This is mine:

The button was approximately tangent with the post on the left side, but protruded outside the post on the right and top edges of the front sight. This meant the center of the FO button was not aligned with the center of the post, creating a conflict that slowed acquisition of a sight picture. It also broke up the post’s square shape, leaving only the upper corners as black, and two of the three edges had lumps in them, rather than being crisp, straight lines. Further, the light intensity of the FO element even in shaded daylight overpowered the adjacent dark edges, making it difficult to focus on them closely. Overall, I felt like I was struggling to hold this revolver with the precision I'm used to.

I looked at the

drop-in options from Novak and was thinking about trying either the

brass bead or

standard tritium dot. I don’t plan for this to ever be a nightstand/HD or CC gun. It will be for square range, maybe some IDPA and carrying in the woods. I was leaning toward the brass bead, as it can more readily be painted various colors and solvent-cleaned back to original, and should be immune to breakage. I haven’t shot with a brass or gold bead before, but it seems like a little brighter spot to help speed with initial sight picture, contrast against black targets and stand out in heavy shade/low sun conditions without overpowering the dark outline of the front post should be pretty effective. I like the traditional look on this revolver, too.

Then I had a brainstorm. The brass bead is $50 plus freight from Novak, and is currently backordered. Replacement FO elements are four for $5 with free shipping, so it's no issue to get back where I started if I want to. I cut off one of the buttons and pulled out the element, leaving a nice, round hole. I then took a chunk of scrap brass rod, made a pin that is a 0.001” interference fit right at the end, cold blued most of it so it blends visually, tapped it in with a small plastic mallet, and added some Loctite 290 to hold on the slip-fit portion. Probably spent the most time getting the swirl mark on the end just right, but it was worth it, because it’s flatter and looks nicer than the Novak part in the photo on their web site. A fun little mini-project in the shop, and my GP upgraded for $0 and no waiting.

As I was looking at everything much more closely, I also noticed there was a slight burr in the notch of the rear sight blade, which made the right vertical side curved and non-vertical. I stoned off the burr and touched it up with a cold blue pen, so the notch is now straight.

Haven’t been to the range yet, but I’m expecting good things.