I have an infuriating problem with my 550 I can't seem to solve. it really slows me down and makes reloading a real chore.

about me: been reloading for about 8 months or so. have loaded about 6k rounds since then, and I only load 9mm. the 550 is my first and only press.

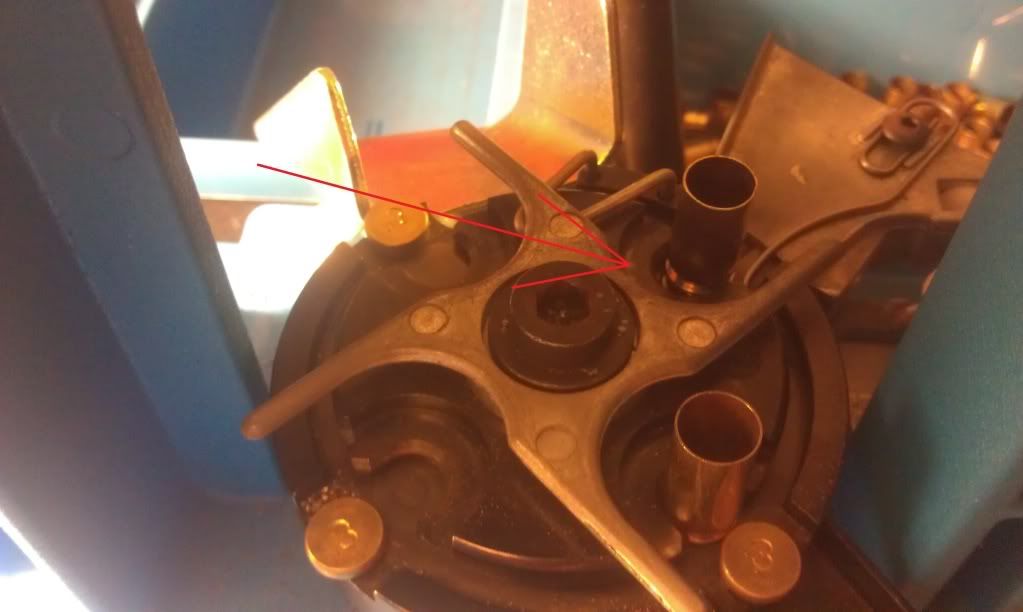

the issue: on station 1, after being resized, the brass has often shifted out of position to be primed. see this handy graphic-

this is where I typically find my brass after it has been resized and deprimed.

(I am nearly certain) this is caused by what happens at station 2. (when there is no case in station 2, the newly resized case in station 1 is always in the correct place to be primed) the powder die often sticks to the case being belled out. the resulting violence of lowering the ram causes enough disturbance to shift the case in station 1 out of position to be primed. sometimes it only moves a little and I can do this little double or triple tap technique with the ram that shifts it back into position. However, mostly I have to push it back in with my thumb.

either way it really destroys my rhythm and even more so that it does not happen with every case. it does happen the majority of the time however.

I don't think I am belling the case out too much with the powder die, causing it to stick. in fact, in an attempt to fix this problem I have backed the powder die back about as much as I can, and occasionally cases are belled so little the bullet doesn't stay upright before its seated, and then I have to reset that. there is definitely minimum belling going on.

maybe the powder die itself is out of spec?

this makes me want to get rid of my 550 and get a XL650. (admittedly this is probably what I should have done first, but I don't feel bad following the Enos FAQ and getting the 550 for my first press to learn on)

from the videos I have seen, it appears the 650 primes the resized case in station 2, in which the case is held in place by some sort of spring loaded mechanism, thus making any 'case drift' impossible and securely holding the case in place to be primed. if I am seeing this correctly, it seems the 650 is definitely the superior press, at least as far as priming is concerned.

any other ideas on what is causing this?

Reply With Quote

Reply With Quote