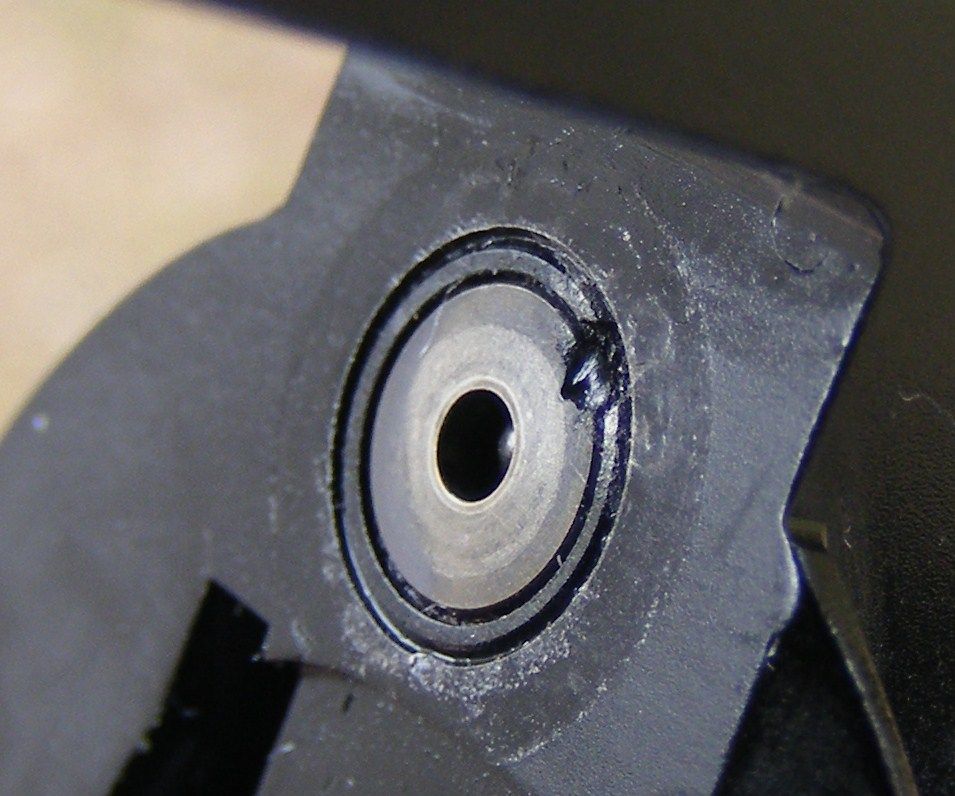

MIM is not a material. It is a forming method.

I have no idea what alloy that bushing is made of, so I'll use an example of a material I am familiar with: 17-4 PH stainless in the H900 condition. The mechanical properties of it are identical whether the part is made through the MIM process of machined out of stock. The only change is about a 1 to 2 percent lower density to MIM vs wrought.

Terms like "real steel" don't add much to the technical discussion. However, parts made through the MIM method have certain design rules/guidelines that need to be followed to prevent premature failures, just like every other metal forming method out there.

Reply With Quote

Reply With Quote